Brazing Alloys

The Brazing Products Division of the Company was formed to specialize in the supply of brazing and soldering materials, particularly Silver Brazing Alloys, Silver Brazing Rings, Silver Copper Phosphorus, Soft Solders and Fluxes.

MAS has extensive stocks of Silver Brazing Alloys, with silver contents ranging from 0% to 55%, cadmium free (or cadmium bearing if your industry requires, not for hobby use), this enables us to provide an “off the shelf” service for delivery to each customer’s requirements.

“MAS combines the highest quality materials at competitive prices, with a customer service second to none.”

Click on any of the images below to access a particular section of information.

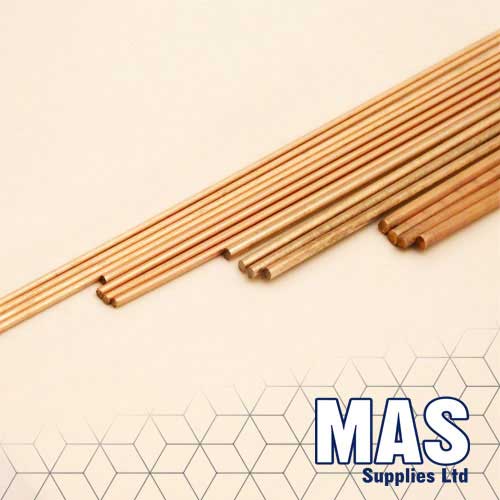

Silver Brazing Alloys

MAS has an extensive stock of silver brazing alloys, with silver content ranging from 20% – 55% cadmium free rods, both bare and flux coated.

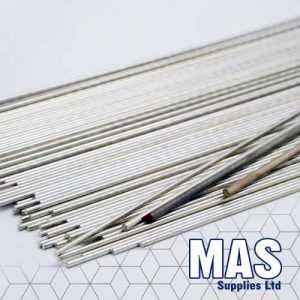

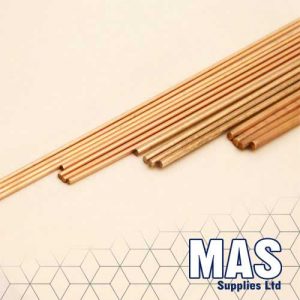

Copper Phosphorous

We stock Copper Phosphorous brazing alloys, with silver content ranging from 0% – 15%, enabling us to offer an “off the shelf” service for each customer’s requirements.

Brazing Rings

MAS also stocks many silver brazing filler rings, in a variety of different sizes and diameters, with silver content ranging from 40% – 55% cadmium free.

Soft Solder

MAS soft solder is manufactured from a grade of solder alloy with purity levels far exceeding the requirements of all national and international standards.

Brazing Flux

MAS stock a wide range of Fluxes in different forms such as powder, paste, cream, gel and liquid, specially formulated to obtain perfect and clean joints due to their high quality.

Soft Solder Flux

MAS soft solder is manufactured from a grade of solder alloy with purity levels far exceeding the requirements of all national and international standards.

- Bohler Welding electrodes & Filler Wires

- Sifbronze electrodes Filler Wire & Fluxes

- Precision Engineering Components

- MMA, MIG, TIG & Plasma Welding Equipment

- Machines- New & Used

- Hire, Service & Calibration

- Protective Clothing

- Silver Brazing Alloys 20-56%

- Silver Foil

- Silver Rings

- Silver Solder

- Fluxes, Pastes & Powders

- Copper- Phosphorous Alloys 0-16% Silver

- Tungsten Tips

MAS Supplies Ltd

10 Manor Lane

Somerby

Melton Mowbray

Leicestershire

LE14 2QD

01664 454403